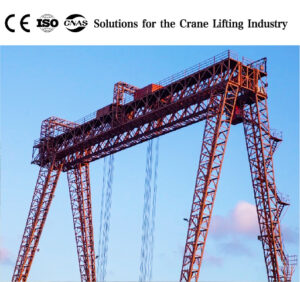

Double Girder Truss Crane: A Comprehensive Guide for Industrial Applications

In the realm of industrial material handling, double girder truss cranes stand out as versatile, high-load solutions designed for heavy-duty operations. Unlike traditional box-beam cranes, their truss-structured girders balance strength, lightweight design, and cost-effectiveness—making them ideal for factories, warehouses, and construction sites requiring large spans and high lifting capacities.

1. What Is a Double Girder Truss Crane?

A double girder truss crane is a type of overhead traveling crane featuring two parallel truss-structured girders (the main load-bearing components) spanning the width of a facility. The truss design—composed of interconnected triangular units—distributes weight evenly, allowing the crane to handle heavy loads while remaining lighter than solid-beam alternatives.

Key components include:

- Truss Girders: Two parallel girders made of steel trusses (typically Q355 or Q235 steel), providing high rigidity and load-bearing capacity without excessive weight.

- Trolley System: A movable carriage (mounted on the girders) equipped with a hoist, used to lift and traverse loads horizontally.

- End Trucks: Located at both ends of the girders, enabling the entire crane to travel along rails installed on the facility’s walls or columns.

- Hoist Mechanism: Electric or hydraulic hoist (rated for 5–200 tons) attached to the trolley, responsible for vertical lifting of loads.

- Control System: Manual (cable pendant) or remote control, with safety interlocks (overload protection, emergency stop) for safe operation.

Its defining advantage: The truss structure reduces self-weight by 20%–30% compared to double girder box-beam cranes, lowering rail and building foundation costs while maintaining a span range of 10–35 meters—ideal for large-scale industrial spaces.

2. Core Advantages of Double Girder Truss Cranes

Double girder truss cranes are favored in industrial settings for their unique blend of performance and cost-efficiency. Below are their key benefits:

2.1 High Load-Bearing Capacity & Rigidity

The triangular truss design distributes stress uniformly across the girders, enabling the crane to handle loads from 5 tons (light industrial) to 200 tons (heavy manufacturing). For example, in steel mills, double girder truss cranes regularly lift 100+ ton steel coils without deformation, thanks to the truss structure’s ability to resist bending and torsion.

2.2 Large Span Capability

With spans ranging from 10 meters (small workshops) to 35 meters (large warehouses or shipyards), these cranes eliminate the need for intermediate support columns—maximizing usable floor space. This is critical for facilities like automotive assembly plants, where unobstructed layouts are essential for production line efficiency.

2.3 Lightweight Design & Cost Savings

The truss structure uses less steel than solid beams, reducing the crane’s self-weight by 20%–30%. This translates to:

- Lower foundation costs: Lighter cranes require less reinforced concrete for rail supports.

- Reduced energy consumption: Smaller motors (15–75 kW, depending on load) power the crane, cutting annual electricity costs by 15%–25% compared to box-beam alternatives.

- Easier installation: Lighter components simplify transportation and on-site assembly, shortening project timelines by 1–2 weeks.

2.4 Durability & Weather Resistance

When constructed with corrosion-resistant steel (e.g., 316L for coastal or chemical facilities) and protective coatings (epoxy or zinc plating), double girder truss cranes withstand harsh environments:

- High temperatures (up to 400°C in foundries, with heat-resistant insulation).

- Humidity and salt spray (common in coastal warehouses or marine yards).

- Dust and debris (in cement plants or mining facilities).

3. Key Applications of Double Girder Truss Cranes

Double girder truss cranes are versatile across industries, thanks to their adaptability to different load requirements and environments. Below are their most common uses:

3.1 Heavy Manufacturing

- Automotive Industry: Lifting (stamping parts), engine blocks, and assembled car bodies (5–50 tons) between production lines. For example, a Chinese automaker’s Chongqing plant uses 12 double girder truss cranes (20-ton capacity, 22-meter span) to streamline assembly.

- Machinery Manufacturing: Handling large machine tools (e.g., 80-ton lathes) or heavy castings during fabrication and installation. The truss design’s rigidity ensures precise positioning of delicate equipment.

3.2 Warehousing & Logistics

- Container Yards: Loading/unloading 20-foot/40-foot containers (30–50 tons) onto trucks or storage racks. The crane’s large span (25–35 meters) covers multiple storage bays, reducing the need for multiple cranes.

- Palletized Goods Handling: In distribution centers (e.g., e-commerce fulfillment hubs), double girder truss cranes with automated hoists move palletized goods (1–10 tons) at speeds of 10–20 meters per minute, improving throughput by 30%.

3.3 Metallurgy & Steel Production

- Steel Mills: Lifting molten steel ladles (50–150 tons) or finished steel coils (30–80 tons) between furnaces and processing lines. Heat-resistant truss girders (with ceramic insulation) prevent deformation at high temperatures.

- Aluminum Smelters: Handling aluminum ingots (20–50 tons) in humid, corrosive environments—corrosion-resistant coatings extend the crane’s lifespan to 15–20 years.

3.4 Construction & Infrastructure

- Bridge Building: Lifting precast concrete segments (30–100 tons) during bridge assembly. The crane’s portability (when mounted on temporary rails) makes it suitable for outdoor construction sites.

- Power Plants: Installing heavy equipment (e.g., 120-ton turbines or generators) in power plant halls. The truss design’s large span (30–35 meters) accommodates the facility’s wide open spaces.

4. Critical Factors for Selecting a Double Girder Truss Crane

Choosing the right double girder truss crane requires aligning the equipment with your facility’s specific needs. Below are the most important considerations:

4.1 Load Requirements

- Rated Load: Determine the maximum weight of the loads you’ll handle (e.g., 10 tons for light manufacturing, 100 tons for steel mills). Opt for a crane with a 10%–20% safety margin (e.g., a 12-ton crane for 10-ton loads) to avoid overloading.

- Load Type: For irregularly shaped loads (e.g., machinery parts), select a crane with a rotating hoist or adjustable spreader. For liquid loads (e.g., molten metal), choose a hoist with anti-sway control to prevent spills.

4.2 Span & Rail Configuration

- Span Length: Measure the distance between the facility’s support columns (e.g., 15 meters for small workshops, 30 meters for large warehouses). Double girder truss cranes are available in spans of 10–35 meters—custom spans (up to 40 meters) are available from manufacturers like Konecranes or ABUS.

- Rail Type: Choose between overhead rails (mounted on the facility’s ceiling) or ground rails (installed on the floor). Overhead rails save floor space, while ground rails are easier to install in existing facilities.

4.3 Work Class & Duty Cycle

- Work Class: Cranes are classified by ISO 4301 (A1–A8) based on usage frequency:

- A1–A3: Light duty (e.g., 1–2 hours/day in small workshops).

- A4–A6: Medium duty (e.g., 4–8 hours/day in distribution centers).

- A7–A8: Heavy duty (e.g., 10–16 hours/day in steel mills).

- Duty Cycle: Calculate the number of lifts per hour (e.g., 5 lifts/hour for medium duty, 15 lifts/hour for heavy duty). High-duty cycles require cranes with reinforced trusses and high-performance motors.

4.4 Environmental Conditions

- Temperature: For high-temperature environments (e.g., foundries), select a crane with heat-resistant paint and motor cooling systems. For cold environments (e.g., -30°C in refrigerated warehouses), choose low-temperature lubricants and insulated electrical components.

- Corrosion Risk: In coastal or chemical facilities, opt for stainless steel trusses or galvanized coatings to prevent rust.

- Dust/Debris: In cement plants or mines, install dust covers on the trolley and hoist to protect moving parts.

4.5 Total Cost of Ownership (TCO)

- Upfront Cost: Double girder truss cranes range from

500,000+ (200-ton, 35-meter span). Avoid budget models—they often have higher maintenance costs.

- Maintenance Costs: Cranes with modular components (e.g., replaceable truss nodes) reduce repair time by 40%. For example, Demag’s double girder truss cranes have a mean time between failures (MTBF) of 3,000+ hours, vs. 1,500 hours for low-cost alternatives.

- Energy Costs: Choose cranes with regenerative braking (recovers 25% of energy during lowering) or LED lighting to cut electricity bills.

5. Maintenance Best Practices for Double Girder Truss Cranes

A well-maintained double girder truss crane can operate for 15–20 years (vs. 8–10 years for neglected units). Follow these strategies to maximize lifespan and performance:

5.1 Daily Inspections (10–15 Minutes/Shift)

- Check the hoist cable for fraying (replace if 10% of wires are broken) and tension (adjust if slack).

- Inspect the truss girders for loose bolts or weld cracks (tighten bolts with a torque wrench if needed).

- Test safety systems: overload alarms, emergency stop buttons, and limit switches (ensure they trigger correctly).

5.2 Weekly/Monthly Preventive Maintenance

- Weekly: Lubricate trolley wheels and hoist gears with manufacturer-recommended grease (e.g., Shell Omala S4 GX 220) to reduce friction.

- Monthly: Clean dust and debris from the truss girders (use a compressed air gun) to prevent corrosion. Check electrical connections (loose wires cause 25% of motor failures) and tighten if necessary.

5.3 Annual Overhaul (2–3 Days)

- Replace worn components: brake pads (every 2,000 hours), filters (oil, air), and cable guides.

- Conduct load testing with certified weights (125% of rated capacity) to verify the truss structure’s integrity.

- Inspect the rail system for alignment (use a laser level) and replace worn rails if they have more than 3mm of wear.

5.4 Long-Term (3–5 Years) Upgrades

- Retrofit the control system with remote operation (reduces labor costs by 20%) or IoT sensors (for real-time monitoring).

- Replace the hoist motor with an energy-efficient model (IE4 or IE5 rated) to cut power consumption by 30%.

- Refurbish the truss girders with a new protective coating (sandblast old paint and apply two coats of polyurethane) to prevent corrosion.

6. Future Trends in Double Girder Truss Cranes

The double girder truss crane industry is evolving to meet the demands of smarter, greener industrial facilities. Key trends include:

6.1 Automation & IoT Integration

- Autonomous Operation: Cranes with AI-powered controls (e.g., Siemens Sinumerik CNC) can lift and position loads without human intervention—ideal for 24/7 operations in e-commerce warehouses.

- IoT Monitoring: Sensors embedded in the truss girders and hoist track temperature, vibration, and cable tension. Data is sent to a cloud platform (e.g., IBM Watson) for predictive maintenance, reducing unplanned downtime by 35%.

6.2 Green Energy Solutions

- Solar-Powered Cranes: Thin-film solar panels mounted on the truss girders supplement grid power, reducing carbon footprints by 20%. Manufacturers like Tadano are piloting solar-integrated models for outdoor facilities.

- Battery-Powered Hoists: Lithium-ion batteries (with 8-hour run time) replace diesel generators in outdoor cranes, eliminating emissions and noise pollution.

6.3 Modular & Customizable Designs

- Modular Trusses: Crane girders made of interchangeable truss segments (1–2 meters each) allow easy adjustment of span length—ideal for facilities with changing layout needs.

- Custom Attachments: Specialized hoists (e.g., magnetic lifters for steel plates, vacuum lifters for glass panels) expand the crane’s versatility, enabling it to handle diverse loads.

Conclusion

Double girder truss cranes are indispensable for industrial material handling, offering a balance of strength, cost-efficiency, and versatility. By understanding their core advantages, selecting the right model for your needs, and investing in proactive maintenance, you can streamline operations, reduce costs, and extend the crane’s lifespan. As the industry shifts to automation and green energy, adopting IoT monitoring or solar-powered solutions will help you future-proof your facility. For personalized recommendations or quotes, search “double girder truss crane manufacturers” on Google to connect with leading suppliers—they can tailor a solution to your specific industrial requirements.